The past can be a great source of inspiration. I was looking at some of the world-renowned historical concrete architecture for inspiration for my new design project. There was a noticeable terraced geometry that I found common in both the Pantheon ceiling (126 AD) and in some of the architecture of Carlo Scarpa.

The Pantheon ceiling (source) on the left and a detail of the Bryon cemetery on the right (source).

The terraced geometries add detailing and generate a beautiful, rhythmic play of shadows onto the concrete works - qualities that are monumental yet refined, present in both of these architectures. I wanted to acknowledge these qualities for the design of a fruit bowl. The brief became: Can a fruit bowl, an everyday object, be reinterpreted to generate the monumental yet refined qualities found in the Pantheon ceiling and some of Scarpa's work?

Design & Iterative Process

The bowl went through three main design iterations. the first iteration was to get a sense of the overall geometries, scale and proportions of the bowl and set a good foundation around mold-making and casting. The second focused on refining the formal aesthetic and functionality of the internal volume of the bowl. The third and final one, on developing the external shell of the bowl.

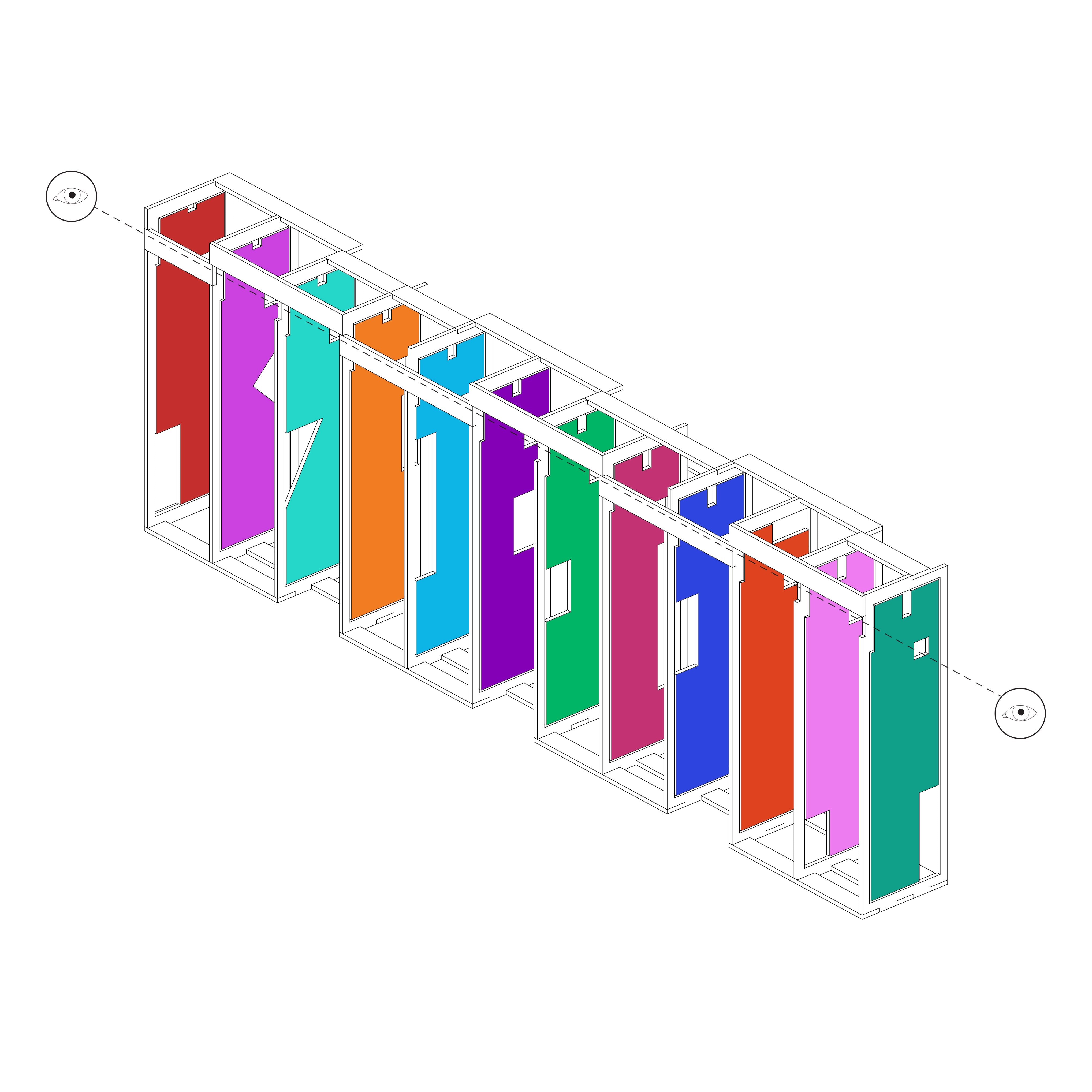

Computer-generated model, showing the initial geometries of the concrete bowl designed around the scale and function of a fruit dish. Raimana Jones.

The first mould was produced with angled melamine panels fixed to a non-stick base.

The first bowl is taken out of its mould! I remember getting a lot of satisfaction at that moment.

Going through this process built a good foundation around mould making and the casting process. The next iteration involved developing the dish part of the bowl, using the precision of the CNC router technology to build the intricacies of the terraced geometries.

Hand drawing of a cross-section through the bowl - shaping the internal terraced forms. Raimana Jones.

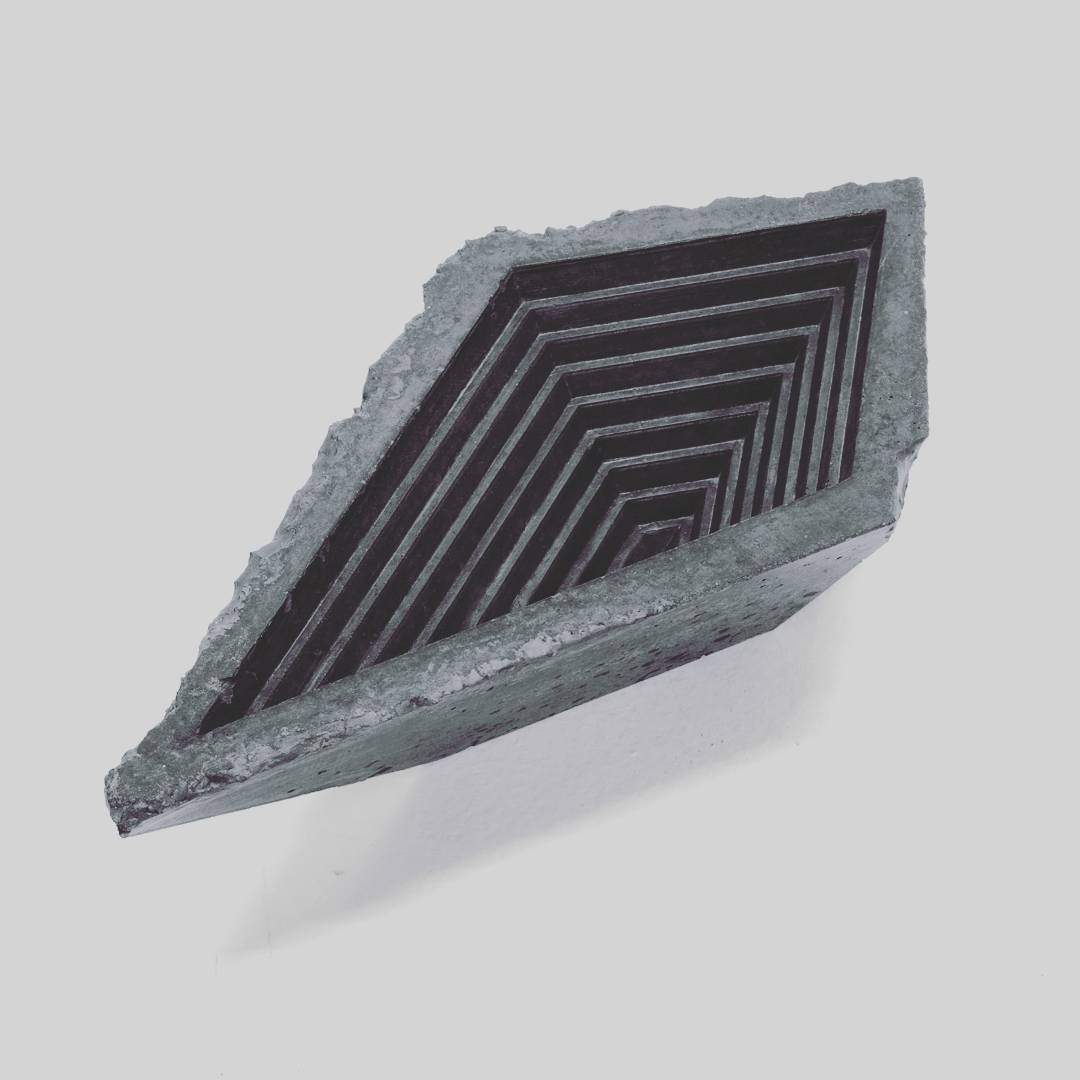

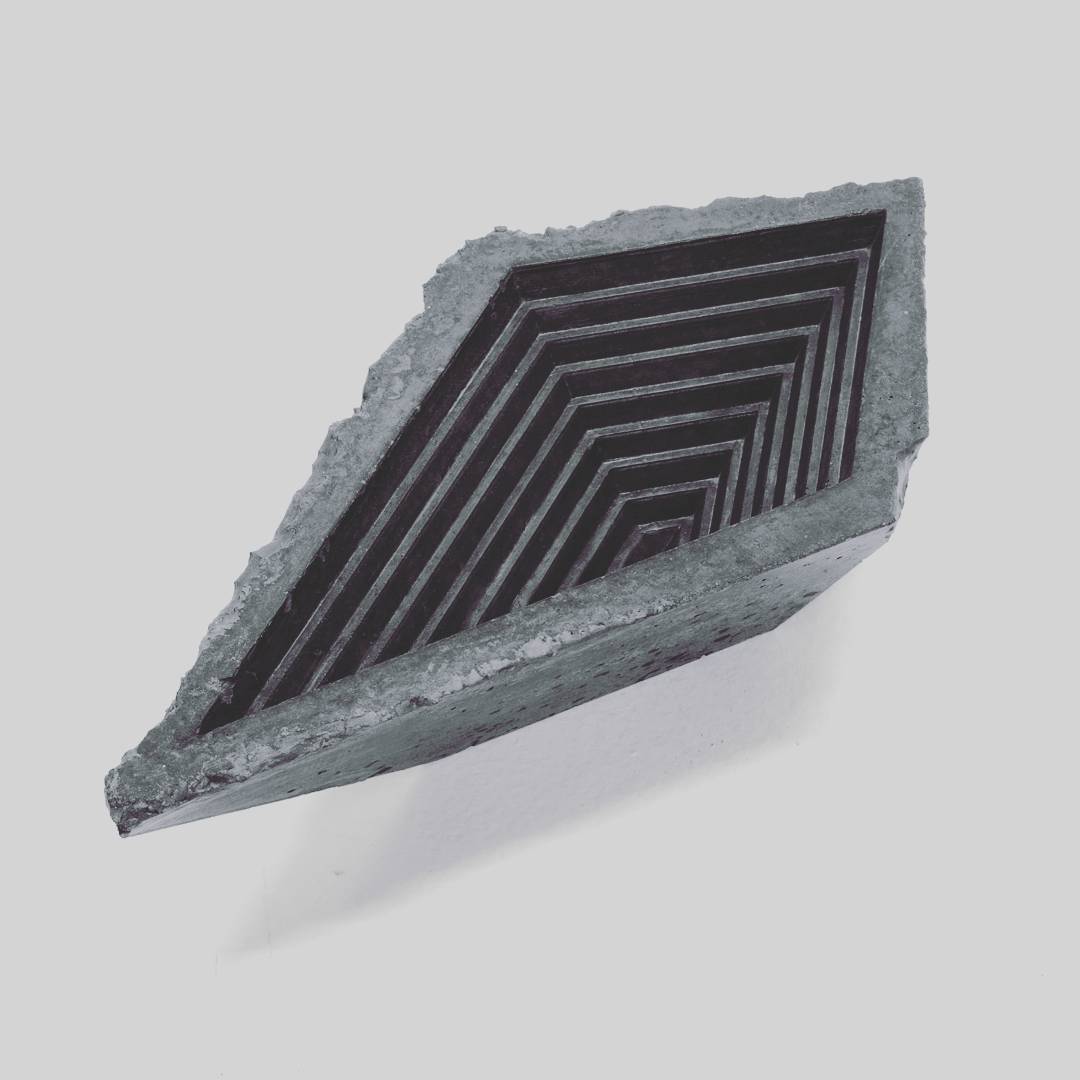

Photograph of a cast of the second iteration of the Terraced Concrete Bowl. Raimana Jones.

Using the CNC router proved to be a good medium for mould making. The final iteration revolved around developing the external shell of the bowl, whilst continuing utilising CNC routing technology.

Sketch of the overall shape of the bowl. Raimana Jones.

Cross-section through the bowl - shaping the external terraced forms in relation to the internal volume. Raimana Jones.

Photograph of an external mould part of the Terraced Concrete Bowl. Raimana Jones.

Photograph of a close up of the external mould part of the Terraced Concrete Bowl. Raimana Jones. There is a subtle striated texture as a result of the CNC milling.

Photograph of all the mould parts of the Terraced Concrete Bowl. Raimana Jones.

To pass from a manual to a more computerised and automated form of mould production was a good transition towards the evolution of the design of the bowl. Personally, the use of CNC routing technology has unlocked more freedom and control around complex form-making.

The section below is the step by step casting process behind the finalised version of the Terraced Concrete Bowl.

Casting Process

1. Outer & Inner Mould Assembly

The mould is made out of three CNC-routed, sealed solid timber parts. Two 'negative' carved blocks make up the outside shell of the bowl and a 'positive' part makes the internal terraced space.

2. Fine Casting Mixture Pour

Our concrete mixture is composed of sand, fine aggregates, portland cement, water and a binding agent, that acts as a reinforcer. Getting a good solid to liquid ratio is key to pick up fine details in the mould and preserve strength. Once the mixture is poured, the mould is vibrated to get rid of air bubbles trapped inside.

Pouring the concrete mixture into the mould.

3. Outer Mold Disassembly

It takes about 24 hours for the casting mixture to dry. The two timber blocks that make up the external shell of the bowl are pulled apart.

4. Inner Mold Disassembly

The bowl is flipped on its base and the internal positive part is removed.

Once all the mould parts have been successfully removed, the sharp edges of the bowl are hand-sanded it is finally coated with a waterproof sealer.

Photograph of a side view of the Terraced. The striated texture from the wood has imprinted itself on the external surface of the bowl, adding a tactile quality. Photograph, Raimana Jones.

Close of the internal volume of the bowl, showing the terraced geometry. Photograph, Raimana Jones.

The monumental yet refined qualities of the Pantheon and Scarpa's architecture has been captured and injected into a small-scale object. A bold architectural object designed for everyday life.

A very thoughtful testimonial written by a practising New Zealand architect who bought one for his wife's birthday:

What appealed to me about the product was its architectural materiality, form and function, the synthesis of all these elements were playfully and creatively engaged. The inherent displacement of the material in the domestic environment challenged preconceptions and for me sets up interesting dialogues with both human perception and the interaction the bowl will have within the context of our historic home.

A big thank you to sculptress Shona Lyon, technician & designer Harold Barton and ceramicist Harriet Stockman for their guidance throughout this process. Your generosity and wisdom prevented a lot of mistakes.

View the Terraced Concrete bowl in our online shop here and Terraced Concrete Vessel here.